The refined Fischer-tropsch wax :SX-F100

High melting point Fischer-tropsch wax:

| Melting point ℃ | 105±5℃ |

| Viscosity cps@140 ℃ | 5-8 |

| Penetration | 6-10 |

| Density G/cm3@25 ℃ | 0.91-0.94 |

| Oil content % | ≤3 |

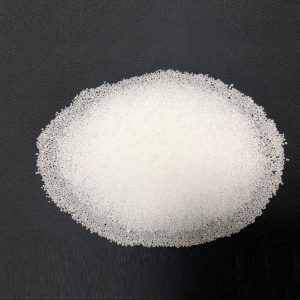

| Appearance | White powder /small round flake bead |

Application:

PVC processing

PVC heat stabilizer

Filler masterbatch

Hot melt adhesive

Brightener

Premium shoes cream

Package and storage

F.T.WAX is packed in kraft paper and woven bags with internal plastic bags with 25KG each net weight. It must not be drenched by rain and scorched by sun. It can be stored for two years.

Production process: Fischer-Tropsch synthesi wax s is a process technology for synthesizing a synthetic gas (a mixture of carbon monoxide and hydrogen gas) into a liquid fuel under the action of a catalyst.The product has a low viscosity at high temperature, which can improve the production speed and fluidity of the product, and enhance the infiltration of the bond surface.Under certain pressure, temperature, and catalyst synthesis, fractionation, solvent extraction, and bleaching, it can be obtained from a monomer hydrocarbon similar to liquid paraffin to a high melting point wax similar to polyethylene wax, with special properties of other natural or other synthetic wax.Originally feto process is used

Fischer-tropsch wax is used with its unique advantages for hot melt glue, plastic lubrication, demolding, pipe, material, profile, ink, paint, light wax, color mother particle, rubber, candle, textile, among which the role of feto waxed in PVC pipe, hot melt glue, ink and color mother grain is indispensable.

| Specification | F110 | Testing standard |

| Melting point ℃ | 110±5 | ASTM D87 |

| Viscosity | 12 | ASTM D445 |

| Penetration(dmm@25℃) | 2 | ASTM D1505 |

| Appearance | flake/powder | ASTM D1321 |

1.As a dispersant During Masterbatch processing. Are widely used in polyethylene masterbatch.

2. As external Lubricant During the Processing of PVC profile, pipe fittings, tube, Plastic molding. lubricant and brightener to enhance plasticization, increase wayward plastic products and surface smoothness.

3. Do ink painting in particular, the road sign paint, marking paint dispersing agent, brightener, and a good anti-sedimentation, the products have good luster and dimension.

4. For a variety of hot melt adhesive, thermosetting powder coatings, PVC compound stabilizer in the production.

5. Are widely used in bottom plate wax, car wax, candle wax products meet all the production, the increase in softening point of the wax products. Increase its strength and surface gloss.

6. In the rubber industry, improve the product, after stripping the surface brightness and smoothness, reduce the amount of paraffin to reduce production costs.