Rapid Delivery for Micronized Wax For Ink - Oxidized polyethylene wax Micronized PE WAX MPE-15 – HAIXING

Rapid Delivery for Micronized Wax For Ink - Oxidized polyethylene wax Micronized PE WAX MPE-15 – HAIXING Detail:

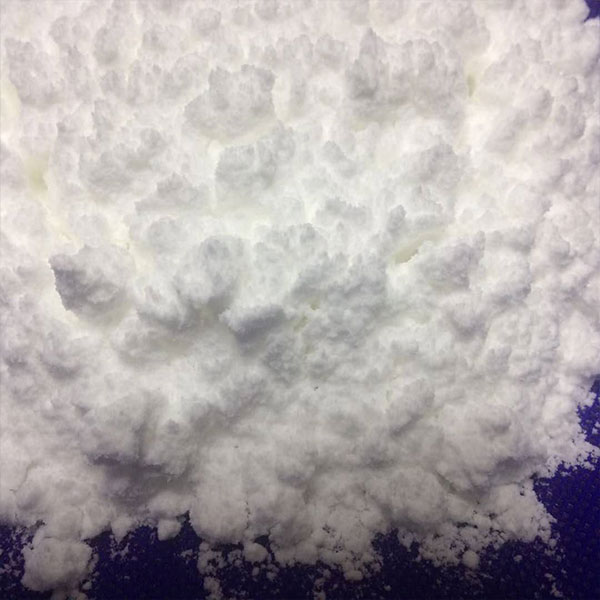

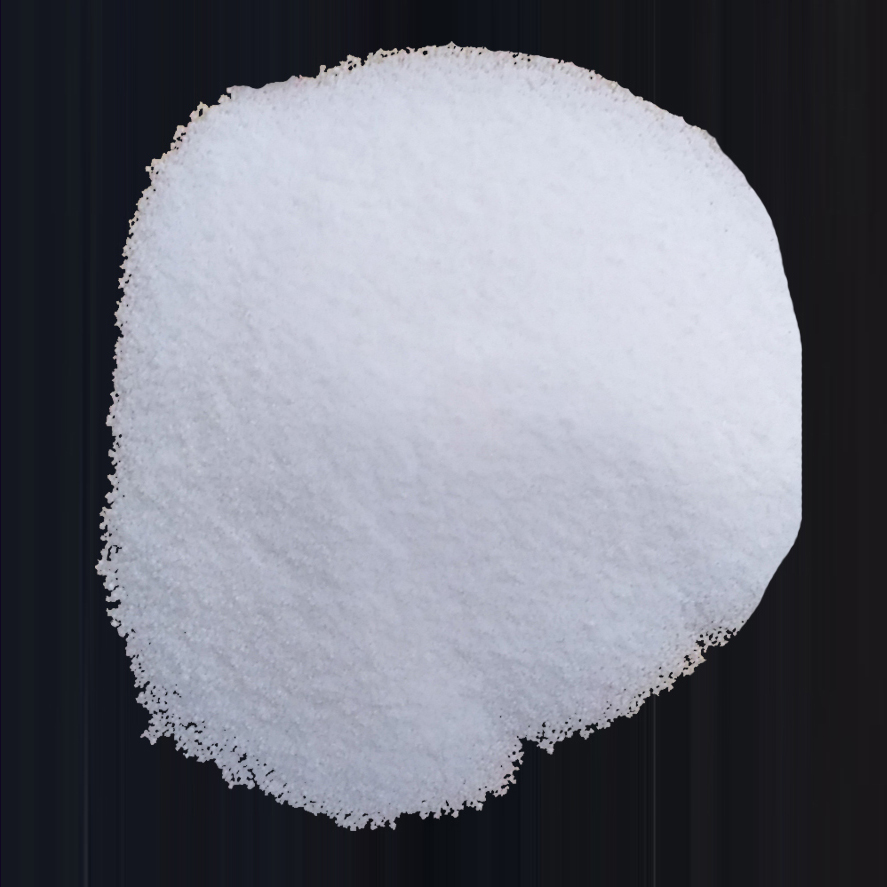

| Appearance | Light yellow Powder |

| Melting point ℃ | 108-116 |

| Particle size μm | Dv 50 4-6 |

| Particle size μm | Dv 90 9 |

Characteristics and Purposes

MPE-15 is a oxidized polyethylene wax used for water-based and solvent-based systems, and is compatible for water-based and solvent-based ink and coatings.

MPE-15 can be used for water-based inks, and water-based paints which provides adhesion resistance, scratch resistance, abrasion resistance, dirt resistance, and so on. Also provides good gloss, smooth soft-feel, and better hydrophobicity and sealing ability.

It can provide the coating with good hardness, and excellent abrasion resistance, with the good performances which the wax emulsion cannot reach. It has excellent dispersity and can get good matting effect at the same time. It can provide good transparency in solvent-based systems.

It has good compatibility for fillers, pigments, metallic pigments, and has the effect of anti-sludging.

For concentrated masterbatch, polypropylene masterbatch, additive masterbatch, filling masterbatch and other pigments or filler dispersant, lubricant, brightening agent, coupling agent.

Rubber and plastic processing lubricant, remover and solvent, EVA wax and all kinds of rubber with good intermiscibility, due to its high melting point and low viscosity, good prompted the resin flow, relative to reduce resin hybrid power consumption, to reduce the mold and the resin adhesion, easy to take off the membrane, internal and external lubrication role, at the same time has good antistatic property.

As ink dispersant, anti – rubbing agent.

As a viscosity regulator of thermal sol.

Aluminum foil compound paper processing AIDS.

For shoe polish, floor wax, wax polish, car wax, cosmetics, matches wax rod, wear-resisting agent of printing ink, ceramics, precision casting, oil absorbent, sealing daub, Chinese medicine wax pill, hot melt adhesives, paint and coating flatting agent, cable feed additive, oil well paraffin remover, crayon, carbon paper, waxed paper, inkpad, photographic materials, textile softener, matrix electronics sealant, crystal Tube sealing agent, rubber processing aid, automobile bottom oil, dental material processing aid, steel rust inhibitor, etc.

Addition and Method of Use

In a variety of systems, the additional amount of the micronized wax is generally between 0.5 to 3%.

It can disperse in solvent-based coatings and printing inks usually by a direct high-speed stirring.

It can be added through the using of a variety of grinding machines, high-shear dispersing equipment.

Can make wax slurry first, and add into the systems when needed, by which can reduce the dispersion time.

Packaging and Storage

Paper-plastic bag, net weight: 20 kg / bag.

This product is non-dangerous goods.

Please store it away from ignition sources and strong oxidants.

Product detail pictures:

Related Product Guide:

To meet the customers' over-expected satisfaction , we have our strong team to provide our best overall service which includes marketing, sales, designing, production, quality controlling, packing, warehousing and logistics for Rapid Delivery for Micronized Wax For Ink - Oxidized polyethylene wax Micronized PE WAX MPE-15 – HAIXING , The product will supply to all over the world, such as: Suriname, Dubai, San Francisco, We have a large share in global market. Our company has strong economic strength and offers excellent sale service. We have established faith, friendly, harmonious business relationship with customers in different countries. , such as Indonesia, Myanmar, Indi and other Southeast Asian countries and European, African and Latin American countries.

This manufacturers not only respected our choice and requirements, but also gave us a lot of good suggestions, ultimately, we successfully completed the procurement tasks.