Micronized Polypropylene Wax PPW-93

Technical Parameters

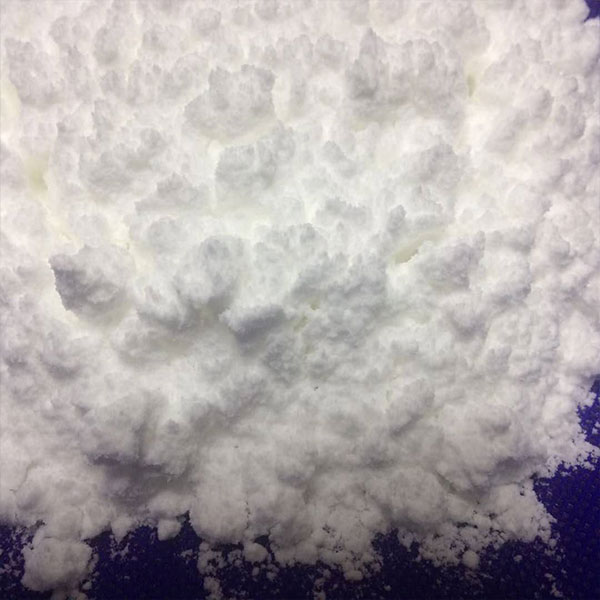

| Appearance | White Powder | |

| Dv50 | 6-7 | |

| Dv90 | 14-15 | |

| Melting Point ℃ | 142 |

Characteristics and Purposes

PPW-93 has uniform particle size and shape, high melting point, good transparency, and can be easily dispersed. PPW-93 is suitable for solvent-based coating, provides help on extinction, can improve scratch resistance, and blocking resistance under higher temperatures.

PPW-93 has synergistic effect, helps to prevent the precipitation of the silica matting agent. When be used with silica, the silica and polypropylene wax proportion is about 1:1 to 4:1.

When added into powder coatings, PPW-93 helps to improve the hardness, and scratch resistance, can assist on matting, will not smoke under 180 °C baking.

Contents and Usage

In a variety of systems, the additional amount of the micronized wax is generally between 0.5 to 3%.

Usually by a way of direct high-speed stirring, it can disperse in solvent-based coatings and printing inks.

It can be added by using a variety of grinding machines, and high-shear dispersing device. Should pay attention to the temperature control when using grind mill.

Can carry out the decentralized processing to make the wax slurry with the wax powder concentration at 20-30%., then add it into the systems when needed, which can decrease the dispersion time.

Packaging and Storage

Paper-plastic bag, net weight: 20 kg / bag.

This product is non-dangerous goods. Please store it away from ignition sources and strong oxidants.