High melting point Fischer-tropsch wax : SX-F110

High melting point Fischer-tropsch wax

| Congealing point ℃ | >100 |

| Melting point ℃ | 108-112 |

| Viscosity cps@140 ℃ | 5-10 |

| Penetration0.1mm(25 ℃) | <1 |

| Volatility | <0.5 |

| Density G/cm3@25 ℃ | 0.91-0.94 |

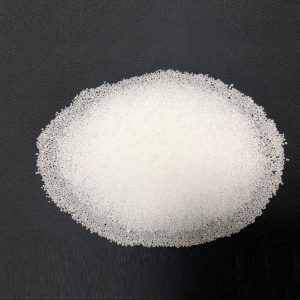

| Appearance | White prill |

The products are produced from natural gas by the Fischer-Tropsch synthesis. Purification is followed by distillation to fractionate the respective products into their respective solidifica-tion point ranges.

The Fischer-tropsch`s wax used in color masterbatch and modified plastic industry , it can help filler`s disperion and excellent smoothness .

Use fischer -tropsch`s wax in PVC as the external lubricants , low viscosity can improve the products producing speed . and can help pigment and filler to disperse. Especially in the high viscosity system `s extrusion has the better application . So, it can save 40-50% compare to the ordinary pe wax .Furthuremore , it can improve the product`s surface gloss absolutely .

Used in concentrated color masterbatch , it can wet pigment effectively and decrease extrusion viscosity .

Fischer tropsch`s wax is not only for PVC. it can also used in hot melt adhesive, release, pipe ,pipe fitting ,polishing wax,paint,coating ,color masterbatch , rubber , candle,textile, Fischer -tropsch is indispensable in PVC ,hot melt adhesive, paint and color masterbatch.

Painting ink and coating : it can improve applied material`s crease resistance and abrasion resistance used in painting ink and coating as the particles powder shape . Add powder coating resin ,it has the lubrication effect in the course of extrusion and reduce screw torque and energy consumption and improve production efficiency.

No any pollution and taste ,can be used directly in food contaction`s hot melt adhesive filed ,

It has higher congealing point and improve the hot melt adhesive`s heat resistance .

Penetration point is little and can increase hot melt adhesive`s strength .

Carbon spreading scope is narrow ,opening mouth time is little , and solidification time is short .