HIGH DENSITY OXIDIZED POLYETHYLENE WAX :SX-36 – HAIXING

HIGH DENSITY OXIDIZED POLYETHYLENE WAX :SX-36 – HAIXING Detail:

| Specification | SX-36 | Testing standard |

| Softening point ℃ | 140±5 | ASTMN 1319 |

| Density(g/cm3@25℃ | 0.98-1 | ASTMD1505 |

| Penetration(dmm@25℃) | ≤1 | ASTMD1321 |

| Molecular weight | 8500-12000 | ASTMD445 |

| Acide value(mgKOH/g) | 16±2 | ASTMD1386 |

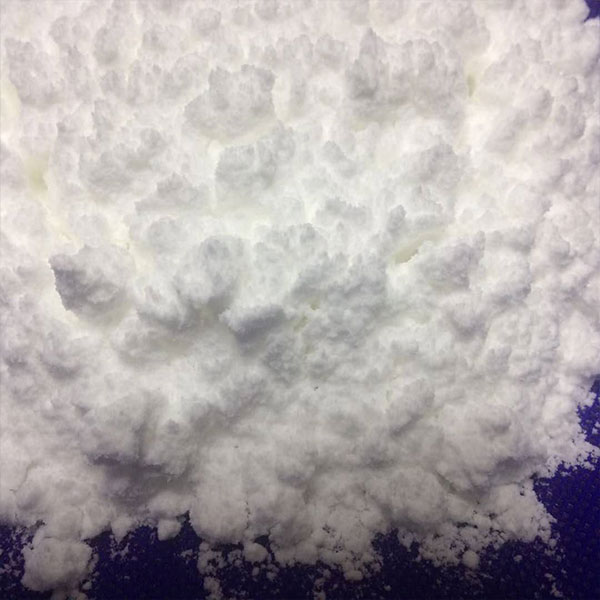

| Appearance | powder | ……………… |

PVC transparent products/ransparent film lubricants

SX-36 high-density oxidized polyetylene wax such as SX-36 shows outstanding performance for transparenet product application ,especially for PVC film produced by blowing and extrusion process .It has been proven to be an unique solution .

Since transparent products have a high requirement for lubricants and also transparency ,and general external lubricnts will make PVC opaque,whereas SX-36 does not affect the transparency of transparent products while also helping melt flow and metal release.It has been recognized as the most effectiv product in the market .

PVC foam board lubricants

SX-36 high-performance lubrican products have been proven to provide effective performance .it can also customize the formulations according to the product requirement to meet diversified demands of lubricants from customers .

It has excellent metal release effect , fusion promote effect , dispersion effect for filler ,reduces plate out/longer working hours , provides a wilder processing window,especially for some special foam products .

PVC edge band lubrciants

For PVC edge band application , it is essential to ensure smooth processing and no immigrated wax to surface and influencing downstream processing ,Such as printing/lamination etc. SX-115 and SX-36 can help PVC edge band enterprises to improve product quality and reduce scrap rate .

It can effectively promotes melt fusion , promotes fusion speed ,improves metal release and reduces plate out effectively .

Applications

PVC foam board

PVC advertising board

PVC cabinet board

PVC transparent tile

PVC floor, PVC SPC floor

Building template

Advantages

Plasticizing: increasing plasticizing while reducing torque;

Demoulding: It can reduce the adhesive force of thermoplastic melting and increase the melt fluidity, improve demoulding and increase the output;

Lubrication: improve gloss and appearance of finished products;

Product detail pictures:

Related Product Guide:

We stick with the theory of "quality first, company first, steady improvement and innovation to satisfy the customers" for the management and "zero defect, zero complaints" as the quality objective. To perfect our provider, we deliver the items together with the fantastic good quality at the reasonable value for HIGH DENSITY OXIDIZED POLYETHYLENE WAX :SX-36 – HAIXING , The product will supply to all over the world, such as: Manila, Maldives, Kuala Lumpur, We warmly welcome domestic and overseas customers to visit our company and have business talk. Our company always insists on the principle of "good quality, reasonable price, the first-class service". We have been willing to build long-term, friendly and mutually beneficial cooperation with you.

Adhering to the business principle of mutual benefits, we have a happy and successful transaction, we think we will be the best business partner.