COMPANY INTRODUCTION

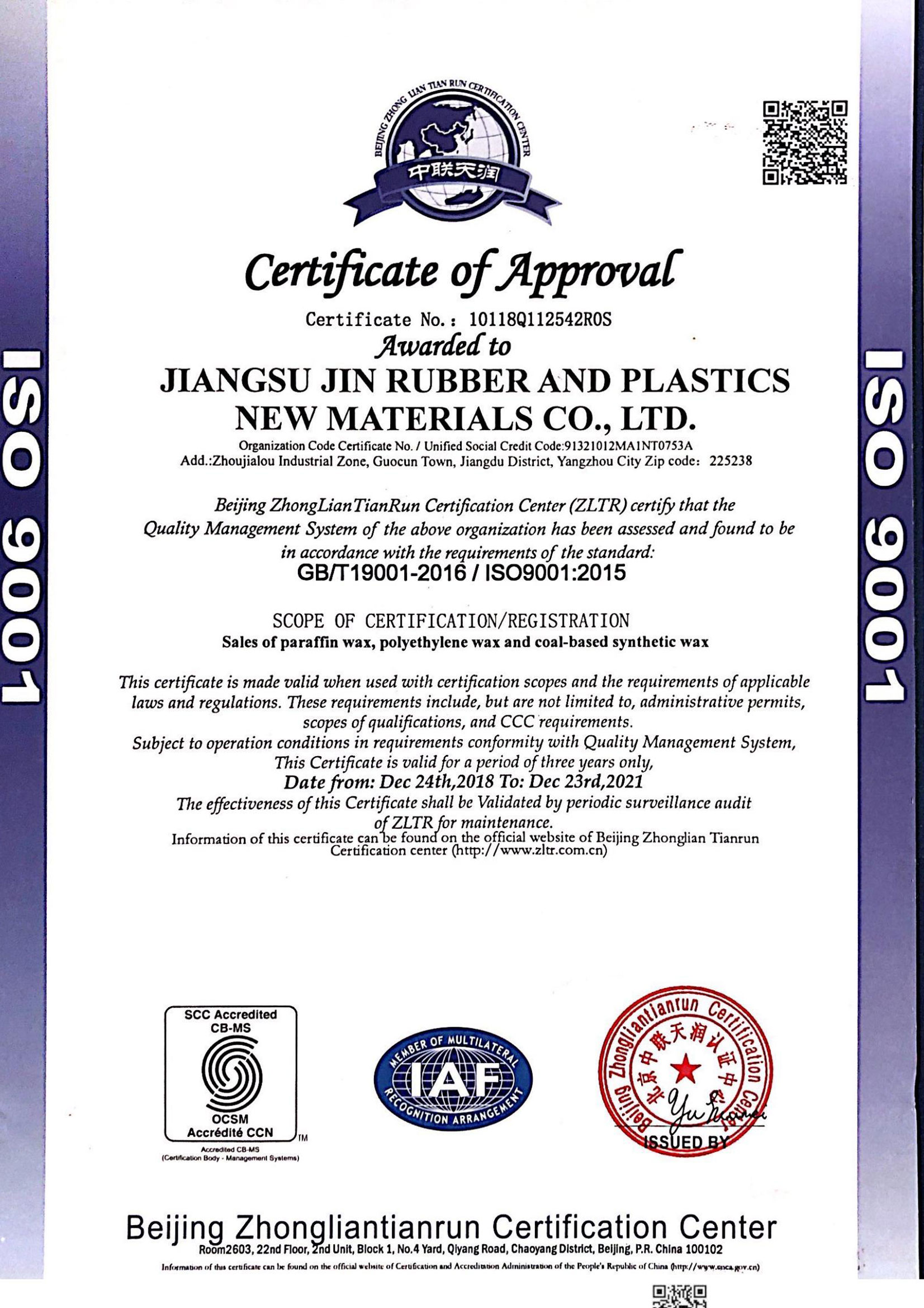

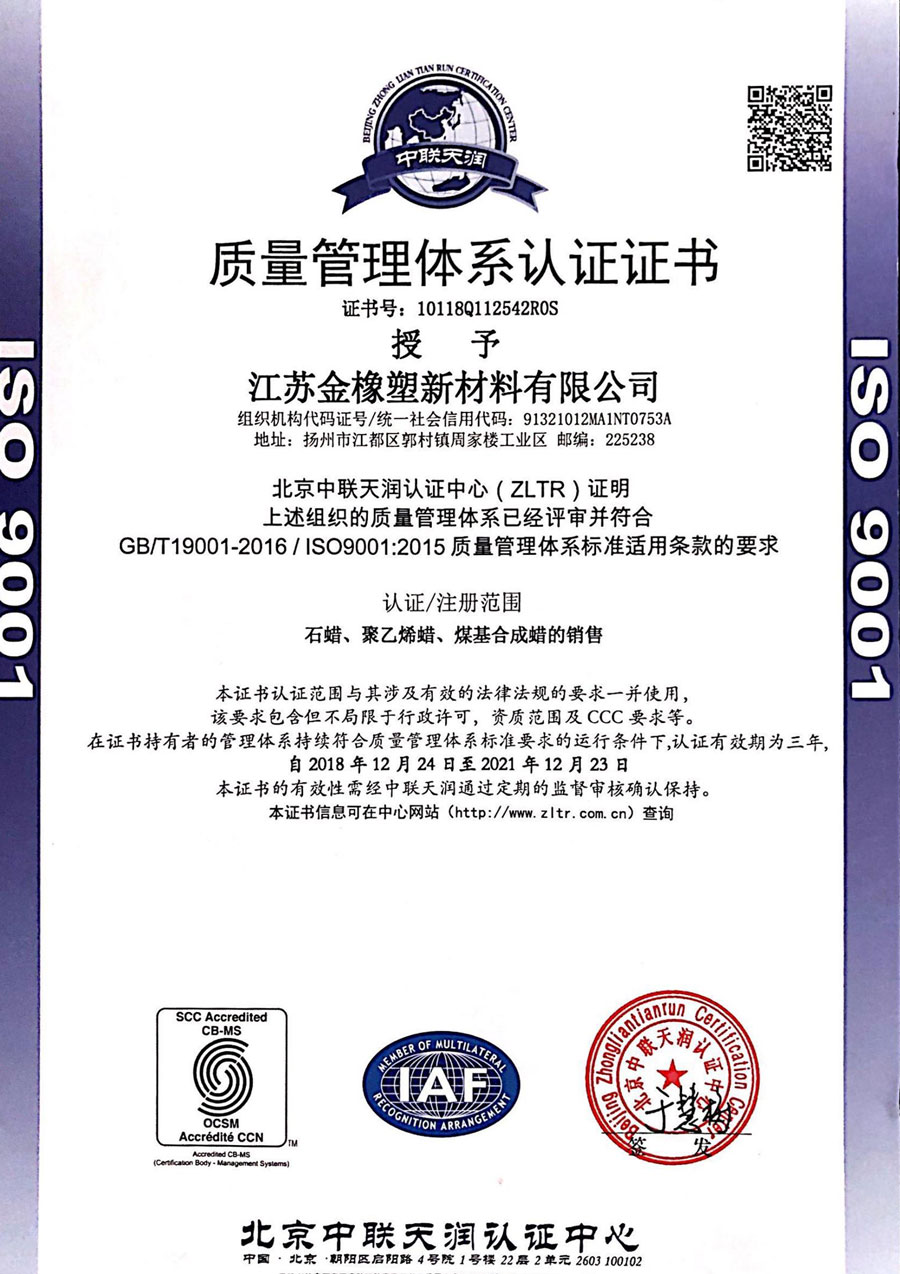

Shanxi Gold Rubber & Plastic Science and Technology New Material Co., LTD. Was established in 2018. We also have other two branch factories of Jiangsu Jin Rubber &Plastic New Material Co.,ltd , Ningxia Xinchen New Materia Co.,ltd . It is an integrated enterprise of researching ,producing ,and development that focus on polymer polyethylene wax, FT wax and other series of wax product . The company locates Dingbian county Shanxi province . We have six patents , 18 utility model patents and 4 high-tech products of Jiangsu province.The production capacity is 100,000.00 tons/year . Advanced production equipment and production process ,dependable coal chemical raw material provide the strong technique and material assurance for our end products . High quality product ,good service make us get the good reputation for domestic and abroad customers . We warmly welcome all of friend to visit our factory and cooperate together for our mutual

FISCHER-TROPSCH WAX (FT WAX)

| Specification | SX-F60 | SX-F70 | SX-F95 | SX-F100 | SX-F105 | SX-F110 | Testing standard |

| Melting point ℃ | 60±5 | 75±5 | 95±5 | 105±5 | 105±5 | 110±5 | STM D87 |

| Viscosity | 4 | 4﹣6 | 6﹣8 | 8﹣10 | 10 | 12 | ASTM D445 |

| Penetration(dmm@25℃) | 20 | 10 | 8 | 6 | 4 | 2 | ASTM D1505 |

| Appearance | flake | flake | flake/powder | flake/powder | flake/powder | Flak/powder | ASTM D1321 |

Applications:

1.PVC Profile ,pipes .

2.Powder coating resin

3.EVA base hot melt adhesive

4.Rubber processing

5.Paint ink

6.Filled masterbatch ,defoamer

7.Fiber products.

Effect

1.Excellent external lubrication effect ,improve the production speed of finished products.

2. Improve lubrication ,reduce processing toqure,reduce energy consumption .

3. Improve the resistance of adhesive ,fast drying.

4. Improve the molding rate,the formation of a harmonious protective layer.

5.Improve anti-scraping, wear resistance,improve loosening, prevent pigment sink.

6.Make calcium powder,talc powder,calcium hydroxide and other inorganic powders dispersed more averagely .

7. Improve wear resistance,tear strength ,anti-wrinkle force,sewing adjust the tactile degree .

POLYEHTYLENE WAX (PE WAX)

| Specification | SX-100 | SX-105 | SX-110 | SX-115 | SX-118 | SX-120 | Testing standard |

| Melting point ℃ | 100±5 | 105±5 | 110±5 | 115±5 | 118±5 | 120±5 | ASTM D87 |

| Viscosity | 5-10 | 30-50 | 40-60 | 300-400 | 400-500 | 400-600 | ASTM D445 |

| Density(g/cm3@25℃ | 0.93 | 0.94 | 0.92 | 0.93 | 0.94 | 0.94 | ASTM D1505 |

| Penetration(dmm@25℃) | 10-15 | 3﹣8 | 2﹣5 | 2﹣4 | 2﹣4 | 2﹣4 | ASTM D1321 |

| Molecular weight | 1000 | 2500 | 3000 | 4500 | 4500 | 5000 | ………… |

| Appearance | Powder | powder | powder | powder | powder | powder |

Application:

1.PVC profile ,pipe ,foaming board,wood plastic.

2.Color Masterbatch,filled masterbatch,modified masterbatch ,functional masterbatch.

3.PVC stabilizer

4.Hot melt adhesive

5.Paint ,paint,road marking paint

6.Paraffin wax,

7.Rubber processing

Effect:

1. Used as excellent external lubricant in PVC profile, pipe, pipe fitti

ng, foam board,WPC products, etc. It has good late-period lubricating ability, and will bring more glossy appearance and lower processing torque.

2.Used as efficient dispersant in masterbatch, filledmasterbatch, modified masterbatch and functional masterbatch. It makes the products inorganic components and pigments dispersed better, and get more beautiful appearance.

3.Used as excellent external lubricant in PVC stabilizer,especially in Ca-Zn stabilizer. Additional use suitable inner lubricant, it will highly improve the overall effect of stabilizer and increase the cost-effective correspondingly.

4.Used in hot melt adhesives can better adjust the products viscosity and hardness, improve its fluidity.

5.Used in paint, coating and the road marking paint, its main performance is heat resistance, deforming, leveling, anti-setting and dispersion. It can increase the products surface hardness, wear-resistance and anti-smearing properties.

6.Used as modifier in paraffin wax, and improve the paraffin’s melting point, crystallinity, etc.

7.Used as releasing agent and protective agent in rubber.

| OXIDIZED POLYEHTYLENE WAX | ||||

| Specification | SX-36 | SX-37 | SX-62 | SX-60 |

| Softening point ℃ | 140±5 | 140±5 | 100±5 | 95±5 |

| Density(g/cm3@25℃ | 0.98-1 | 0.98-099 | 0.92-0.95 | 0.92-0.95 |

| Penetration(dmm@25℃) | ≤1 | ≤1 | ≤5 | ≤4 |

| Viscosity (cps@140℃) | 8500-1100 | 10000-15000 | 200±50 | 100±50 |

| Acide value(mgKOH/g) | 16±2 | 7-18 | 30±2 | 20±5 |

| Appearance | powder | powder | powder | powder |

Effect

1. With good compatibility ,to provide good internal and external lubrication ,dispersion

Improve surface smoothness ,promote plasticizing demoulding and yield

2. Good dispersion emulsifier ,release agent, improve flexibility and moisture resistance

3. Increase the intensity ,gloss,combustion complet ,no black smoke .

4. Improve the dispersion ,improve the appearance of the finised product

Application

1. In PVC film, profile , pipe ,plastic processing

2. After emulsification for the paper industry ,printing and dying and garment industry ,water-based ink ,water-based shoe polish

3. Wax products

4. Hot melt adhesive ,adhesives .

| MICRONIZED POLYEHTYLENE WAX | |||||||||||

| Specification | MPE-85 | MPE-51 | MPE-43 | MPE-27 | MPE-26 | MPE-25 | MPE-22 | MPE-21 | MPE-20 | MPE-15 | |

| Melting point ℃ | 137 | 115 | 97-103 | 126 | 125-128 | 115 | 110 | 110 | 110 | 108-116 | |

| Particle size μm | DV 50 | 6 | 10 | 4-6 | 6 | 6-8 | 8-10 | 5-6 | 4-6 | 7 | 4-6 |

| DV 90 | 12 | 14 | 9 | 14 | 11-13 | 14 | 12 | 9 | 18 | 9 | |

| Appearance | powder | powder | powder | powder | powder | powder | powder | powder | powder | powder | |

Effect

1. Good hardness , wear resistance,anti-adhesion and stain resistance ,improve the abrasion resistance,scratch resistance and smooth feeling

2. Anti-adhesion, extinction effect is abvious grnding and slippery ,repainting,anti-sinking,good air permeability,immprove the salt fog and moisture-proof effect, paint to improve the performance of paint remover,improve the leveling of baking enamel surface.

3.The friction coefficient is very low,superior wear resistance,sliding,scratch resistance,heat resistance,corrosion resistance,chemical resistance.

4. High melting point,adhesion resistance,lubricity ,good dispersion ,improve the ink wear resistance,transparency .

5,Can give luster and heat stability ,coating smooth and so on .

Application

1. Wood paint,industrial paint,powder paint .

2. Paint and paint manufactruing .

3. POTS ,coils ,wood coatings , powder coating and printing inks .

4. Water-based ,solvent ink coating

5.Leather processing